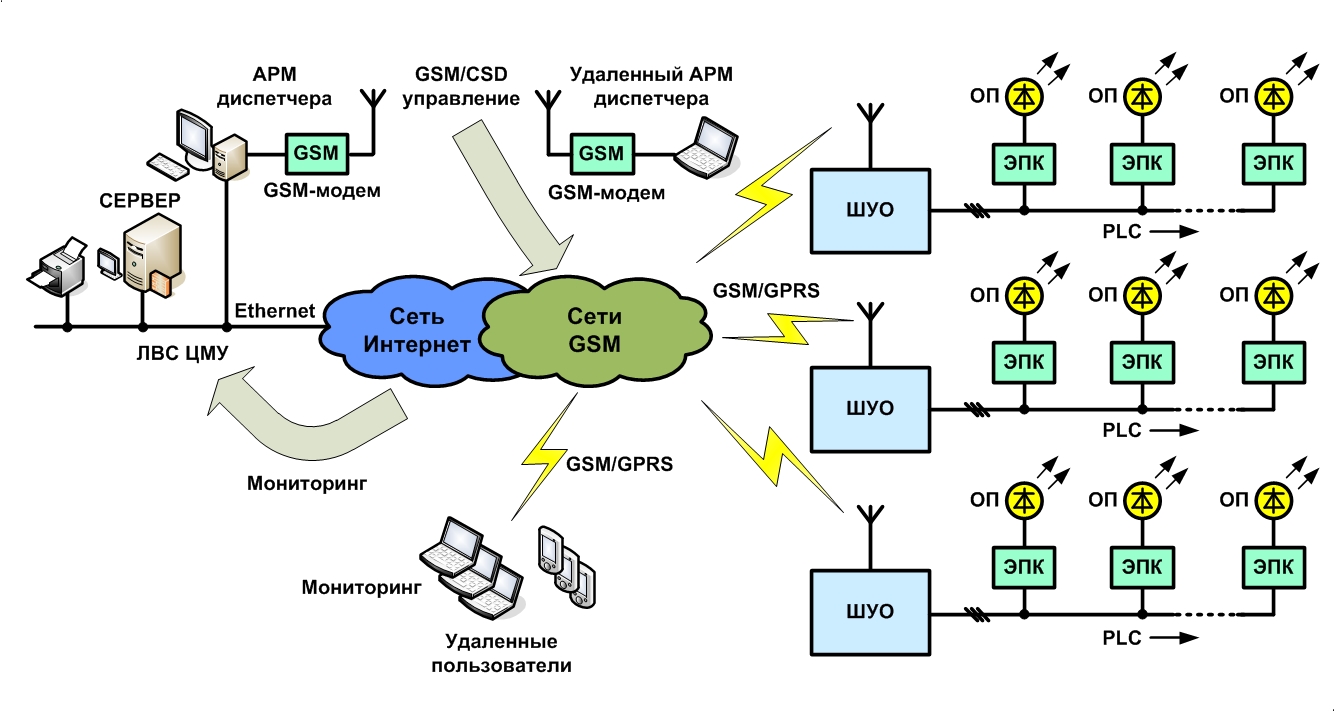

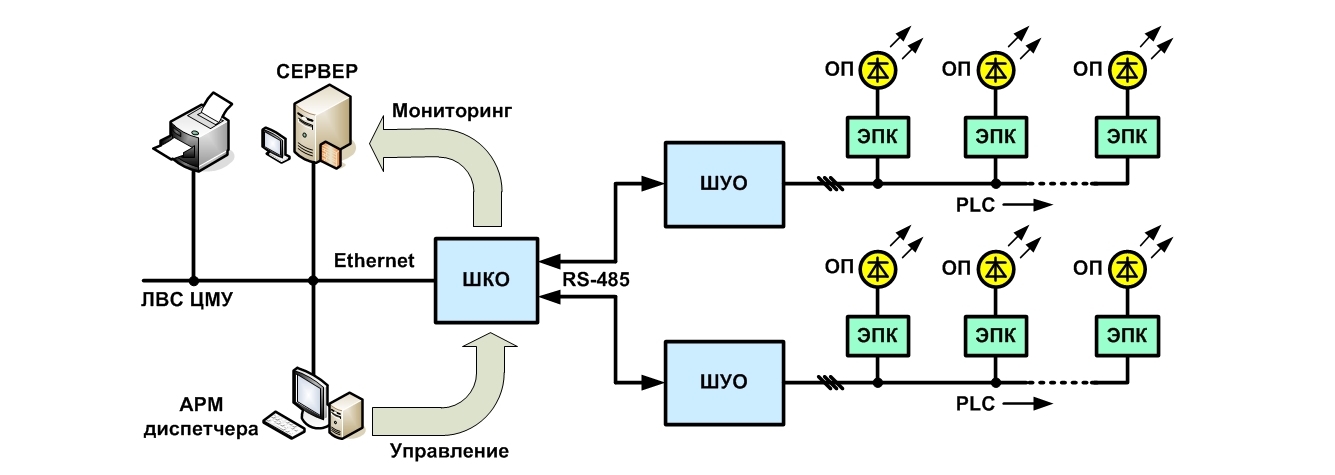

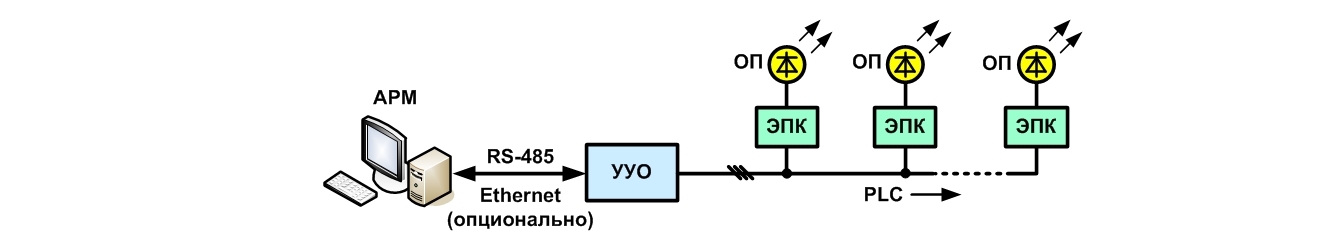

The Figures 1 -3 show the examples of the main technical solutions used to create the automated illumination control systems (AICSs) for various purposes. Each lighting fixture (LF) has the power supply network command receiver (PSNCR) installed into it. The lighting control cabinets (LCCs) operate under the annual astronomical schedule. If necessary, a natural illumination level meter can be connected to the CLL. Fully functional control can be implemented in either three-phase or single-phase lighting networks.

According to the diagram shown in Figure 1, these are mainly the outdoor illumination automated control systems (OIACSs) that are being created for the facilities divided territorially at which the lighting system operation modes have to be controlled in vast spaces, such as communities, motorways, corporate infrastructure facilities, recreation and tourism objects, etc.

The diagram shown in Figure 2 corresponds as a rule with the structure of the outdoor illumination automated control systems (IOACSs), the indoor illumination automated control systems (InIACS), or combined illumination for objects and facilities occupying large areas but located separately (local objects and facilities) in which the prompt visual supervision of electrically powered equipment and lighting fixtures operation mode is impossible. Such objects and facilities include railway stations, assembly halls of industrial enterprises, cargo handling terminals, sea ports, river ports and airports, hotel facilities, etc.

Implementation of the lighting control presented in Figure 3 is efficient for small separate (local) objects where it is possible to carry out a virtually uninterrupted supervision of condition and operation modes of lighting fixtures; this schematics is useful in simplified combination of LCCs and light controllers (LCs). Such objects include, for instance, fuel and gas stations, sports venues, cultural objects and recreation sites, shopping malls, etc.

Abbreviations used in figures: ЛВС = LCN – local computer network; ЦМУ = MCS – monitoring and control center; АРМ = AW – automated workstation; ШУО = LCC – lighting control cabinet; УУО = LC – light controller; ШКО = CEC – communication equipment cabinet; ОП =LF – lighting fixture; ЭПК = PSNCR – power source network command receiver; PLC – technology of address command transmission via power supply network.

RUS

RUS ENG

ENG